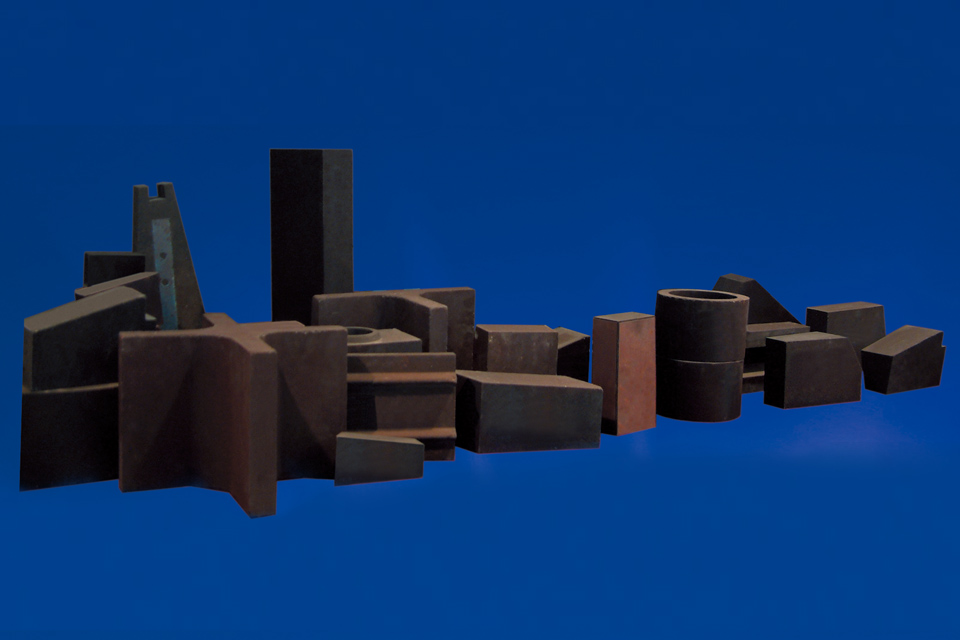

Magnesia Zirconia

Burned magnesia brick QMz-91-QDM-98 1s made from one or two grades of high quality magnesia of different MgO content. The higher MgO content and burning temperature, the more periclase crystal direct bonding of products and the better corrosion resistance it will get and the higher temperature performance it will achieve. Fused rebonded magnesia brick is made from fused magnesia with large periclase crystal, high bulk density, and low apparent porosity. It is better at high temperature volume stability, high temperature strength, ad slag resistance.

Magnesia brick is widely used in safety linings of steel making furnaces, working linings of hot metal mixers, ferroalloy smelting furnaces and non-ferrous metallurgical furnaces, preheating zones, cooling zones of lime kilns and glass tank regenerators.

QMZ-91L is low density magnesia brick with bulk density of 2.75~2.80g/cm', used in safety linings of steel making converters, electric arc furnaces etc. Being light and heat insulating, the brick is a kind of energy saving refractory material.

QDMZ-98Z, QMZr-12A and QMZr-12B are magnesia bricks with addition of ZrO2. They have better high-temperature strength and thermal shock resistance than fused rebonded magnesia bricks. QDMZ-98Z is mainly used for calcining zones of lime kiln. QMZr-12A and QMZr-12B are mainly used for glass tank regenerators.

*Datasheet could be provided by request.