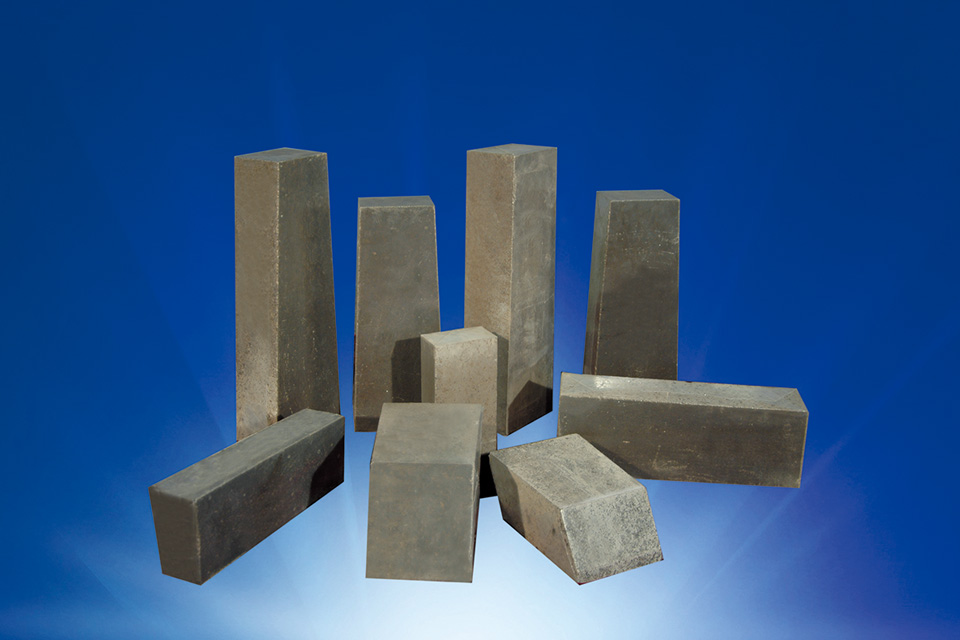

Magnesia-Spinel Series

Magnesia-alumina brick QML-80 is made from high purity magnesia and high quality bauxite. Magnesia-alumina spinel is formed in the matrix of the brick to give very good high temperature performance and stable resistance to thermal shock. This product is mainly used in non-ferrous smelters and glass tank regenerators.

Magnesia-alumina spinel brick QSMJ series use high purity magnesia and high quality magnesia-alumina spinel as raw material, the main crystal phases are periclase and magnesla-alumma spinel, this series of products give good performance under high temperature and higher resistance to thermal shock. QSMJ-2 & QSMJ-5 are widely used in the transition zones and burning zones of cement rotary kilns, which achieve great performances among hundreds of plants.

Periclase compound spinel brick QSMGe-6A and QSMJ-S is widely used in the burning zones of dry-process cement rotary kilns. QSMGe-6A, made from magnesia-ferrite spine clinker and chromite, resists to the erosion from cement clinker. In the production magnesia-ferrite spinel clinker is to replace part of magnesia chromite and taking better advantage of Fe2O3, together with Cr2O3, with the addition of Fe2O3, QSMGe-6A improves coating ability, brick structure and the spalling resistance.

In the production of QSMJ-5, Magnesia-alumina spinel is used to replace chromite to meet the chrome-free requirement. It has outstanding coating ability; the thermal shock resistance and conductivity has been optimized by adjusting the ratio of MgO/AlO,. QSMJ-5 is an ideal product for dry-process cement rotary kilns.

*Datasheet could be provided by request.