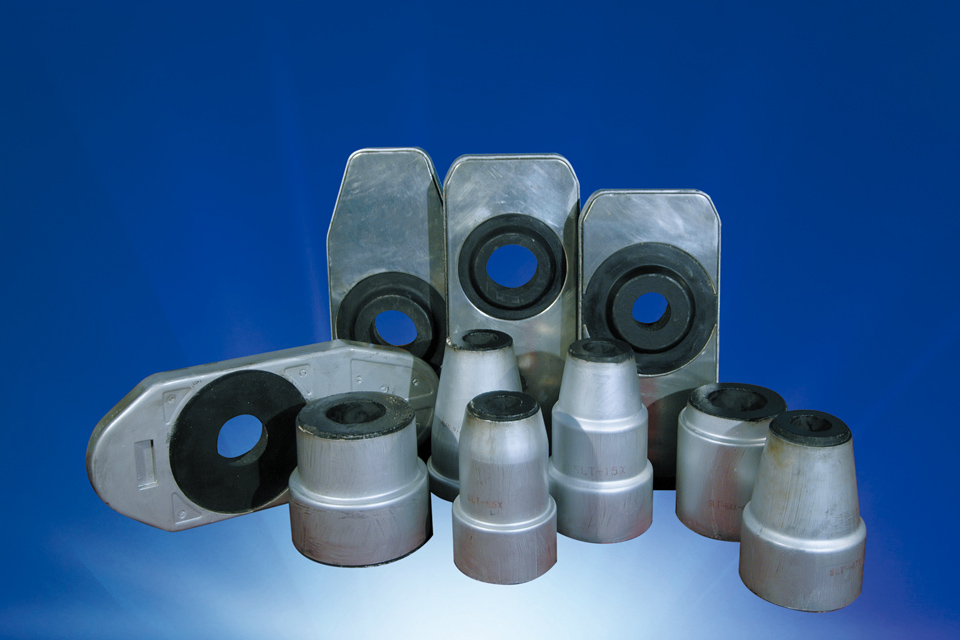

Magnesia Carbon Series

Magnesia-carbon brick is resin-bonded, made from dead-burned or fused magnesia and graphite, shaped under proper temperature, finished after heat treatment. Anti-oxidant such as metal and carbide etc. is often added to improve its oxidation resistance and high temperature strength. When magnesia-carbon brick is used under high temperature, carbon skeleton bond is formed, and excellent refractory properties of original components are maintained since MgO and C are not eutectic.

Carbon has good conductivity and low thermal expansion coefficient, it owns large wetting angle against slag to resist slag penetration effectively, so thermal spaling and structural spaling is very difficult to happen. The fatal weakness of magnesia refractories, i.e. structural spaling due to deterioration of slag penetration, has been greatly avoided. With such series of properties, magnesia-carbon brick becomes ideal lining materials with outstanding resistance to erosion, spaling and thermal shock. It's widely used in metallurgical furnaces such as steel making converters, EAFs, refining ladles etc.

Magnesia-alumina-carbon brick is made from Al2O3, (corundum, high quality calcined bauxite, homogenized bauxite and andalusite etc.), MgO (fused magnesia, dead burned magnesia) and graphite. It has good properties of resistance to molten steel abrasion, low thermal conductivity and high thermal insolation. Its appropriate residual expansion contributes to good integrity of bricking lining. Magnesia-alumina-carbon brick is a kind of proper refractory material for ladle sidewalls and bottoms.

Magnesia-alumina-carbon brick has the properties between magnesia-carbon brick and alumina-magnesia-carbon brick, which can be used in the intermediate section between ladle slaglines and sidewalls, and ladle sidewalls as well.

Alumina-silicon carbide-carbon brick is mainly made from Al2O3, (corundum, high quality calcined bauxite, homogenized bauxite and andalusite etc.), silicon carbide and graphite, and anti-oxidant, aditives etc. can be added for specific applications. It has strong resistance to slag erosion, abrasion, and thermal shock; it also has good high temperature strength. It is a kind of proper lining material for hot-metal ladles, torpedo cars to hold and pretreat hot metal.

Manufactured with special technologies, magnesia-dolomite-carbon brick is made from high quality magnesia, magnesia-dolomite clinker and graphite, bonded with anhydrous resin. It has good properties of resistance to metallurgic slag, spalling and thermal shock, purifying steel, and especially excellent stability in high temperature vacuum working conditions.

Magnesia-dolomite-carbon brick is the first choice for the following applications: sidewall of ladle for tyre cord steel making, refining ladle lining and GOR converter floor for stainless steel making, ladle for desilicating or dephosphorizing converters, especially ladle sidewall and bottom of vacuum refining VOD.

*Datasheet could be provided by request.